2019/8/15 10:17:27 3764

· Following recent equipment innovation success including the SLAC Conversion Press, and SLAC’s Global Supplier Award-winning SC-DCP-B2006 Digital Printer, SLAC Group is once again leading industry progress with its new Optimised End

· A revolutionary step for the can making industry due to little or no long contracts and no royalties involved

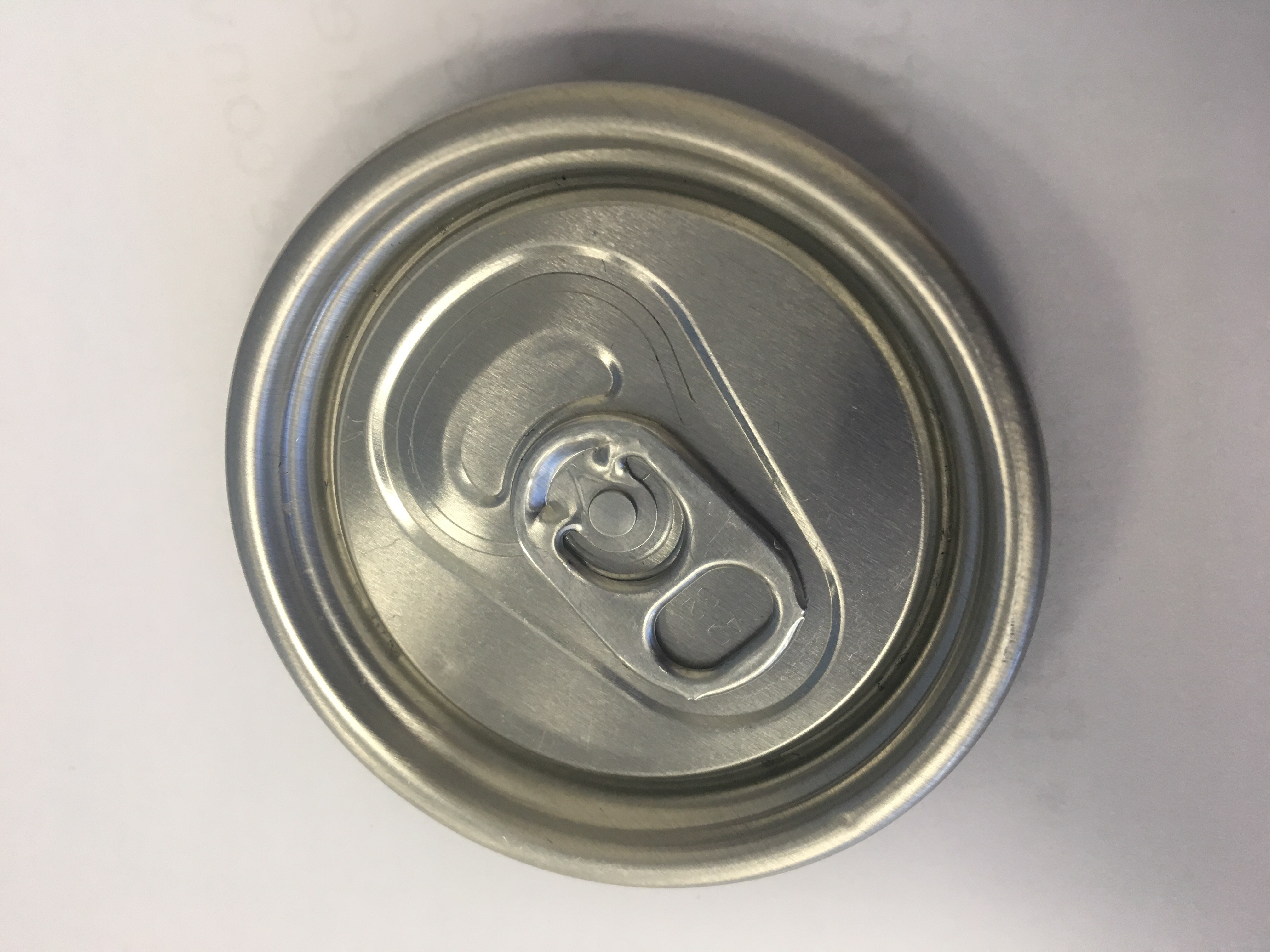

SLAC Optimized End shell for 200 and 202 beverage can sizes

SLAC Group is setting the standard for innovation within the can making industry, with the introduction into the beverage can end market of its SLAC Optimized End for 200 and 202 beverage cans.

Unlike existing lightweight ends, the SLAC Optimized End doesn’t charge royalties for every end made; a license isn’t always needed. A world first for the can making industry, can makers now have the option for more flexibility, as chief operating officer and chief marketing officer at SLAC Group, Chris McKenzie, explains:

“When we did our market research, one of the biggest frustrations customers had was the fact they were locked into contracts for end production,”。 he says. “They want to be free from contracts where possible; can makers like to control their markets; they don't like to be controlled by their markets. With our new Optimized End, we make things simple, without the frustrations of royalties, and being tied into long contracts.”

With no set-up costs, and an excellent return on investment, the SLAC Optimized End compares favourably with existing 200 and 202 ends. With costs savings of over 12% and 10% respectively, and the ability to retrofit onto existing systems, the SLAC Optimized End also has comparable metal economics and technical attributes to existing lightweight ends.

The SLAC Optimized End is the brainchild of SLAC Group’s R&D department in Suzhou, China, where a team of over 130 engineers have a separate team that are charged with working solely on product innovations. This team of engineers has led to a number of impressive commercial products recently, including the Hexad Conversion Press, and the company’s Digital Printing MiniLine. The SLAC Optimised End is another cutting-edge product to the company’s portfolio.

“We have been looking at adding this to our stable for quite a period,” says McKenzie. “We have been resisting the idea, and then two years ago we decided to progress with the project, due to the groundswell of support out of Asia Pacific, where they wanted to see another option for ends. We started to work on a ‘what if?’ scenario.

“We have been working with a customer and have now commercialized the Optimized End into the field. Six months ago, discussions turned to a major international customer, who wanted to look at the possibility of rolling it out into their portfolio.

“We are now confident to say it’s time to launch this officially on the basis that we want to be known as innovators. Every single one of our innovations has life, and our track record over the past few years shows how we’re leading the industry, rather than following”

The SLAC Optimized End has all the benefits of existing ends for the beverage can industry, without the need for costly contracts and royalty complications. This has the potential to be a game changer for the industry.

Technical specifications for SLAC Optimized End (SOE200 & SOE2020)

· Thickness - SOE200: 0.208mm, SOE202: 0.208mm

· Average cut edge - SOE200: 67.63mm, SOE202: 69.84mm

· Weight - SOE200: 2.02g, SOE202: 2.15g

· Saving potential – SOE200: 12.55%, SOE202: 10.79%

· Buckle pressure: SOE200: >720kpa, SOE202: >720kpa

official account

official account